by making production processes more efficient.

Reduce your

energy use

by +20%

The future is here: specialized AI agents

for industrial manufacturers

We reduce energy use & machine downtime

in production processes

Water management

Furnaces

Air compressors

Extractor hoods

Grinders

Case Studies

Automatizing operation efficiency

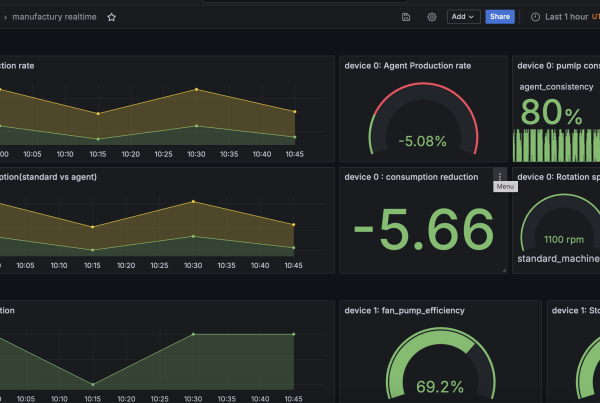

Real time monitoring

We built a digital twin of your devices to monitor energy consumption, key process parameters and savings.

Autonomous energy efficiency & predictive maintenance

Our AI agents:

- Learn from real-time process data, metering & actions

- Continuously identify optimal settings on machines

- Implement the improvements in production

- Prevent downtimes before they occur

SaaS aligned with your savings

- Reduce operation costs, at a time of rising input prices

- Abate carbon footprint, at a time you’re asked for more sustainable products

- Slash carbon offset costs & unlock demand-response benefits

Proud to be backed by

Meet the team

+50 years of experience in energy, engineering and data science

Bardia

Rafieian

CTO

+10 years of experience in Software engineering (Huawei) & Cloud. +5 YOE in deep tech startups.

Ph.D. in NLP (Natural Language Processing) & Artificial Intelligence (UPC, Barcelona) and Software Engineering degree (Iran).

LinkedIn

Ph.D. in NLP (Natural Language Processing) & Artificial Intelligence (UPC, Barcelona) and Software Engineering degree (Iran).

Mohammad

Peyman

RL Data Scientist

Ph.D. in Reinforcement Learning and Artificial Intelligence at UPV (Spain).

MSc in Modelling of Science & Engineering (UAB, Barcelona). Mechanical Engineering Degree in Teheran.

Yusef

Ahsini

Ouariaghli

ML Engineer

Brilliant Machine Learning Engineer with a lot of experience in developing ML models, despite of his young age. Multiple Hackathon winner while finalising his MSc in Math Research & Data Engineer at UPV.

Backend

Engineer

coming soon

Brilliant software engineer with a background in front and backend. With international experience and a Cloud based system mastery.

Óscar

Morales

Sales engineer

Process Engineer with a MSc in Energy efficiency (Univ. of Stuttgart). International experienced professional with a background in energy in EnBW (Germany) and COMSA (Spain).

María

Guasch

Morgades

Industrial Ph.D. as

RL Data scientist

Great mathematician with experience in a biotech startup. She will soon join BeChained enrolling an Industrial Ph.D. and helping us develop our trailblazing products.

Mariana

Vargas

Sales Engineer

Environmental Engineering degree in East London and international experience, she brings Technical experience in energy infrastructure and buildings.

Janne

Öfversten

Advisor

Currently Head of Digital & Sustainability Innovations at Kone in Finland. His carrier comprises two decades of experience in Nokia (across IoT, energy and power, and technology) and one in Digital Innovation at Kone.

LinkedIn

Oliver

Wolf

Advisor

Currently Customer Experience Manager at Deutsche Bahn.

He worked in the development of Long Distance Trains and different International Executive tenures at Lufthansa.

LinkedIn

He worked in the development of Long Distance Trains and different International Executive tenures at Lufthansa.

Reghu

Ram

Advisor

SVP of Fintech Products and Digitals at Deutsche Telekom.

His career comprises Executive roles in Deutsche Telekom and SAP; as well Executive education in Insead and Harvard Business School.

His career comprises Executive roles in Deutsche Telekom and SAP; as well Executive education in Insead and Harvard Business School.

Latest blog posts

🌍💡 AI Agents: The Future of Industrial Efficiency

Industrial manufacturing is at a crossroads—facing rising energy costs, inefficiencies, and stagnation. But AI-driven industrial agents are changing the game. 🚀In my latest article, I explore how BeChained is leveraging AI to optimize water management,…

Peak Shaving, Load Shifting vs. AI-Powered Dynamic Energy Optimization

(Original article from Medium) Introduction With rising energy costs, market volatility and increasing emphasis on sustainable practices, manufacturers are under pressure to optimize energy use. Traditional methods like peak shaving and load shifting have…